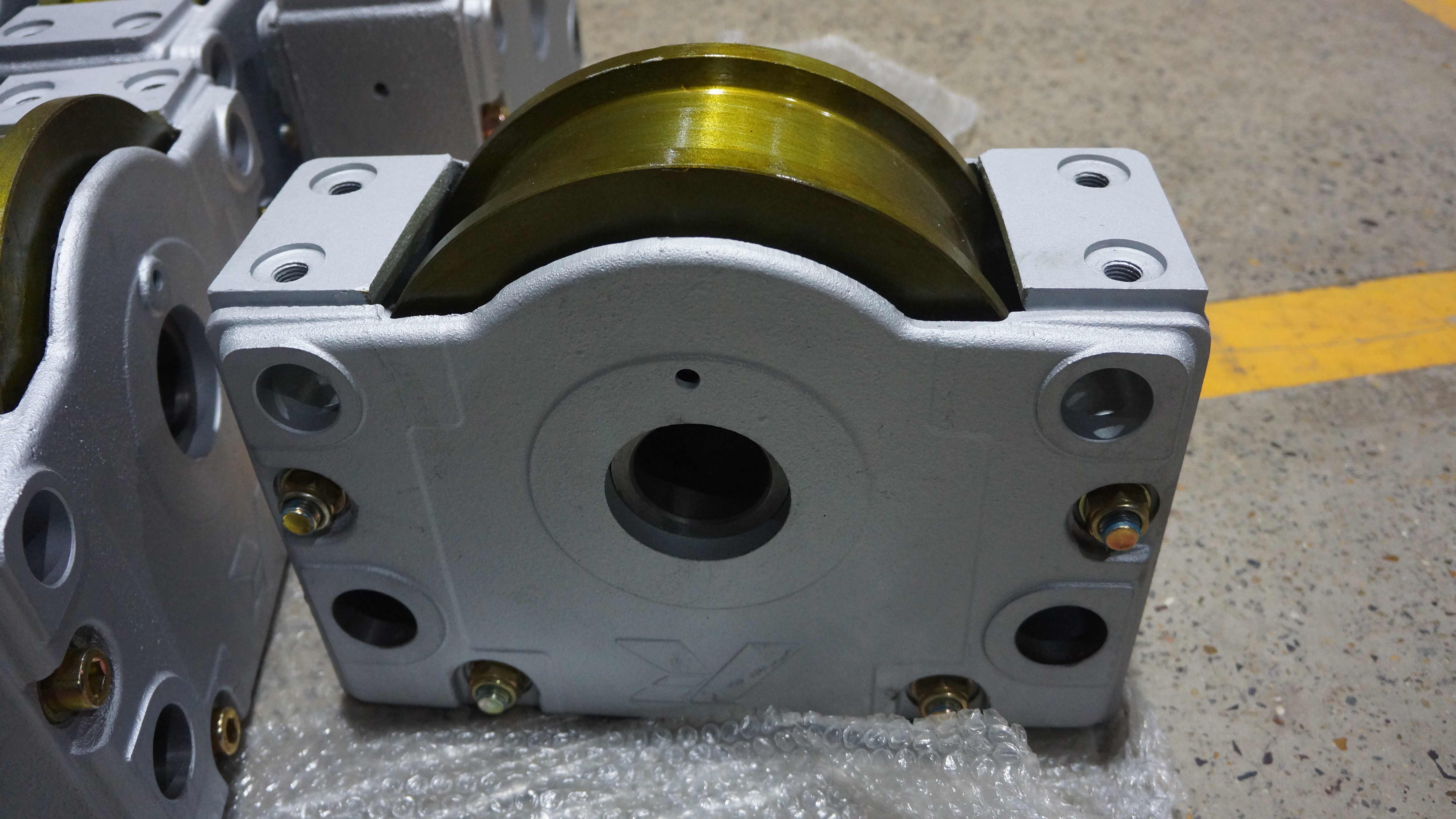

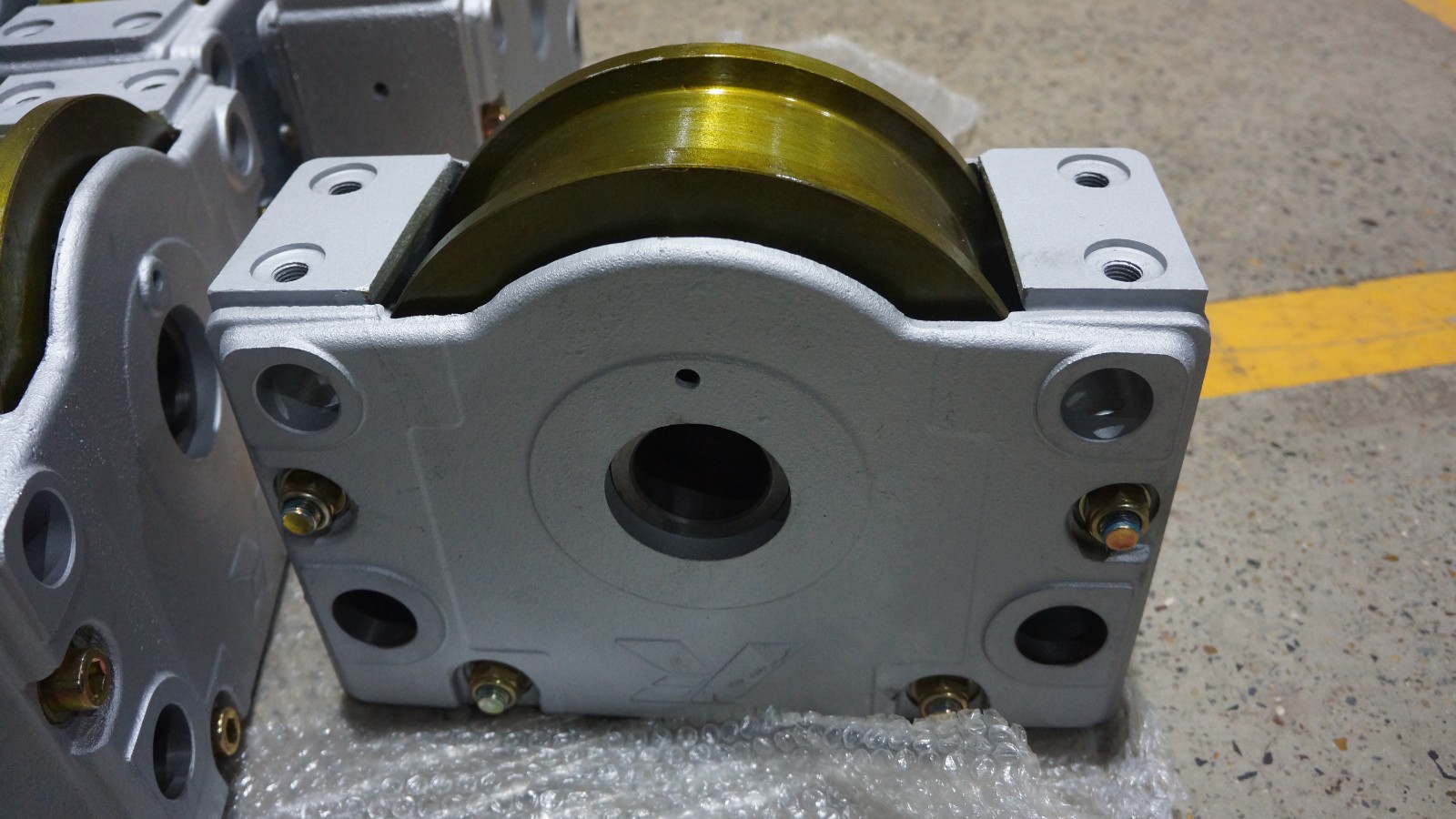

The DRS wheel block system is a key component used in the end beam of the crane. It is designed to provide smooth and efficient travel function to ensure that the crane can operate stably in various working environments. The DRS wheel block system is mainly composed of running wheels, bearings, boxes and other parts. The traveling wheels are made of high-strength materials and have good wear resistance and impact resistance, and can withstand various complex forces during the traveling process of the crane. The bearing is responsible for reducing the friction between the walking wheel and the box body and improving walking efficiency. The box plays a supporting and protective role to ensure that the running wheels and bearings can still work normally in harsh environments.

In the crane end carriage beam, the DRS wheel block is responsible for supporting and guiding the crane to move, ensuring that the crane moves smoothly and accurately on the track. In addition, it can withstand various dynamic loads generated by the crane during lifting and moving, ensuring the stability and safety of the crane.

DRS wheel block system is widely used in various types of crane end carriage beams, such as overhead cranes, gantry cranes, etc. In overhead cranes, DRS wheel block system is installed on both sides of the end beam to provide a stable traveling track for the crane. In gantry cranes, DRS wheel block system is installed at the bottom of the gantry legs to ensure that the crane can move smoothly within the span.

Installation method

1. Check whether the wheel block and its accessories are intact to ensure that there is no damage or omission during the installation process.

2. Determine the installation position and direction of the wheel block based on the actual situation of the crane end carriage beam.

3. Use special tools to fix the wheel block on the end beam to ensure a firm and stable installation.

4. Adjust the height and level of the wheel block to maintain good contact and cooperation with the track.

5. Check the gap and lubrication between the wheel block and the track to ensure smooth and stable walking.

Product features

1. Made of high-strength materials, it has good wear resistance and impact resistance, and can withstand various complex forces.

2. The bearings are made of high-quality lubricating materials, which can effectively reduce the friction between the running wheel and the box body, and improve the walking efficiency and service life.

3. The structural design is compact and reasonable, which reduces the overall size and weight and facilitates installation and maintenance.

4. Adapt to various harsh environments, such as high temperature, low temperature, moisture, corrosion, etc., ensuring that the crane can operate normally in various environments.