5 Tips for Extending Crane Operating Life

Introduction:

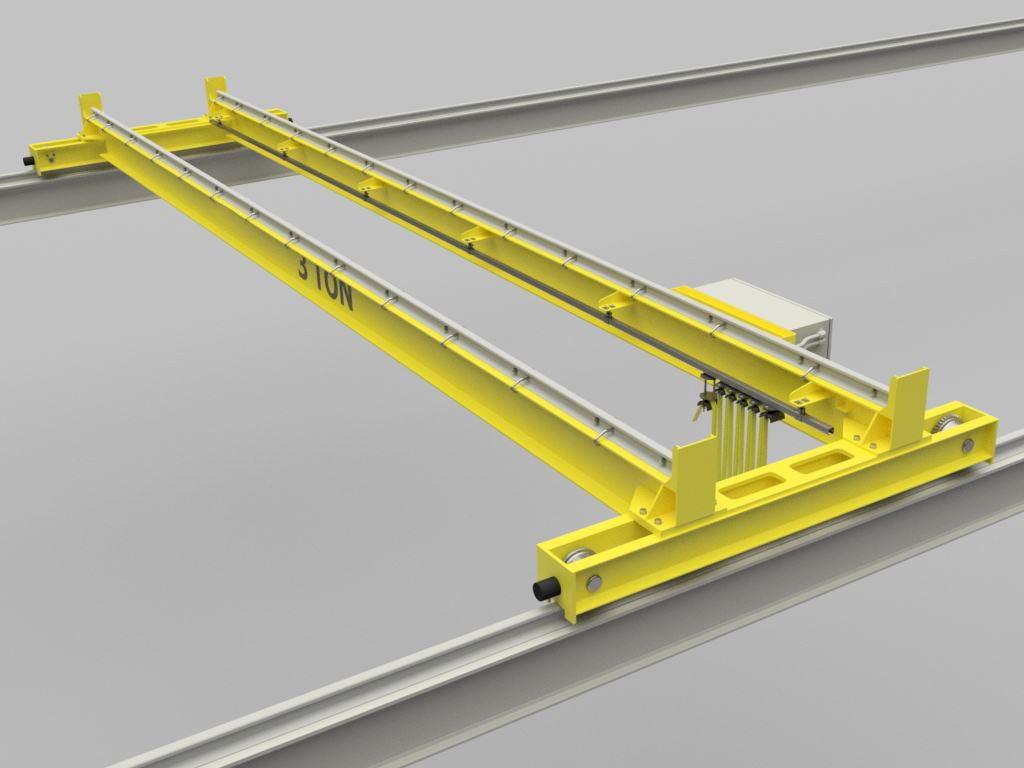

Cranes are essential heavy machinery used in various industries for material handling and lifting operations. To maximize productivity and ensure cost-effectiveness, it is crucial to extend the operating life of cranes. By implementing certain strategies and maintenance practices, crane owners and operators can significantly improve lifting mechanism longevity and performance. In this article, we will explore key steps to enhance crane service life.

1. Regular Maintenance and Inspections:

Take overhead cranes for example, implementing a comprehensive maintenance program is vital for crane longevity. Regularly inspecting and servicing the bridge crane's components, such as cables, hoists, brakes, and electrical systems, helps identify potential issues at an early stage. Prompt repairs and replacements prevent further damage and extend the crane's operating life.

2. Lubrication and Cleaning:

Proper lubrication of moving parts is crucial to reduce friction and wear, Regularly applying the recommended lubricants to bearings, gears, and other crucial components can significantly enhance crane performance and longevity. Additionally, keeping the crane house clean, free from debris and regularly removing dirt and grime helps prevent corrosion and ensures smooth operation.

3. Operator Training and Skill Development:

Proper training and skill development of crane operators play a crucial role in maximizing equipment life. Well-trained crane operators are more likely to operate the crane within its specified limits, avoiding undue stress and strain on the crane's components. They will also be knowledgeable about safety protocols, preventing accidents that can lead to equipment damage.

4. Load Management and Safe Practices:

Overloading a crane is a common cause of premature wear and damage. Adhering to load capacity limits and employing safe lifting practices significantly improves the crane's operating life. Operators should carefully assess the weight of the load, use appropriate rigging techniques, and follow proper lifting procedures to avoid unnecessary strain on the crane's structure.

5. Environmental Factors:

Consider the environmental conditions in which the crane operates. Extreme temperatures, humidity, and exposure to corrosive substances (in chemical laboratory) can accelerate wear and deterioration. Taking measures such as applying protective coatings, using corrosion-resistant materials, and implementing proper storage procedures in harsh environments can help to assist your work efficiently.

Conclusion:

Normally, a branded and authoritative electronic system and control system has a good performance, e.g. electric components, motors from Siemens, Schneider, SEW, etc. Regular maintenance, proper lubrication, operator training, load management, and environmental considerations are still vital aspects of crane operation and service life. Investing time and resources in these practices not only enhances the crane hoists’ performance but also improves safety, reduces downtime, and ultimately increases productivity and cost-effectiveness.

KUNFENG Cranes is a professional crane manufacturer in China. With more than 15 years manufacturing experience, we have been helping businesses with customized lifting solutions for decades. Contact us to find an optimum crane lifting solution for your business!