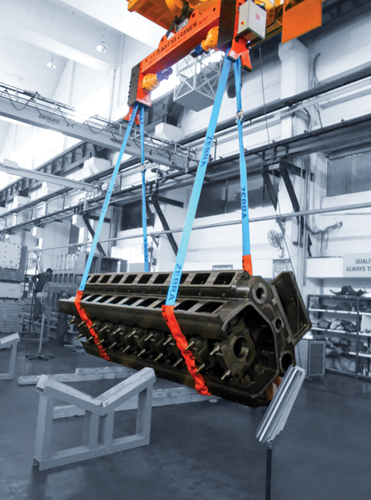

Suspension load turning device is a device used in conjunction with a overhead crane. By suspending the flipping mechanism on the crane, it can move, flip, lift and lower large workpieces. This kind of equipment has the characteristics of high precision, fast response, strong load-bearing capacity, large working space, and flexible degree of freedom, and can meet the turning needs of workpieces of different specifications and shapes.

In steel mills, suspension load turning devices are particularly widely used. Since steel needs to go through multiple processes during the production process, such as cutting, welding, grinding, etc., these processes often require turning and moving the steel. The traditional flipping method often requires a lot of manpower and material investment, is inefficient, and has certain safety hazards. The application of suspension load turning device can easily solve these problems. It can quickly and accurately flip steel to any angle to meet various processing needs and greatly improve work efficiency and safety.

Working principle

When the workpiece needs to be turned over, the operator can control the crane through the remote control or console to move the turning mechanism over the workpiece. Then, the turning mechanism clamps and fixes the workpiece through devices such as telescopic arms or chains. Next, the crane starts to move, driving the turning mechanism and the workpiece to move together. When the workpiece moves to the appropriate position, the turning mechanism starts to work, and the workpiece is turned over in the horizontal or vertical direction through a hydraulic or electric drive device. Finally, when the workpiece is flipped to the required angle, the flipping mechanism releases the workpiece, and the crane moves it to the next process for processing.

Product advantages

● It can realize fast and accurate turning and moving operations, greatly reducing the time of manual handling and turning workpieces, thereby improving the efficiency of the entire production line.

● The turning process is highly automated, which also reduces the labor intensity of workers.

● Using remote control or console operation, the operator can stay away from the turning site, avoiding safety accidents caused by improper operation or workpiece falling off.

● It can adapt to workpieces of different specifications and shapes to meet different processing needs.

● The structure design is reasonable, the operation is stable and reliable, and it can meet the needs of long-term and high-intensity production.

Get In Touch

Have inquiry or question for our products, please kindly leave us your message and we will get back to you within 24 hrs. You can also contact us via email.